Model No.︰GA-01

Brand Name︰Jetvision

Country of Origin︰-

Unit Price︰US $ 720 / Ton

Minimum Order︰1 Ton

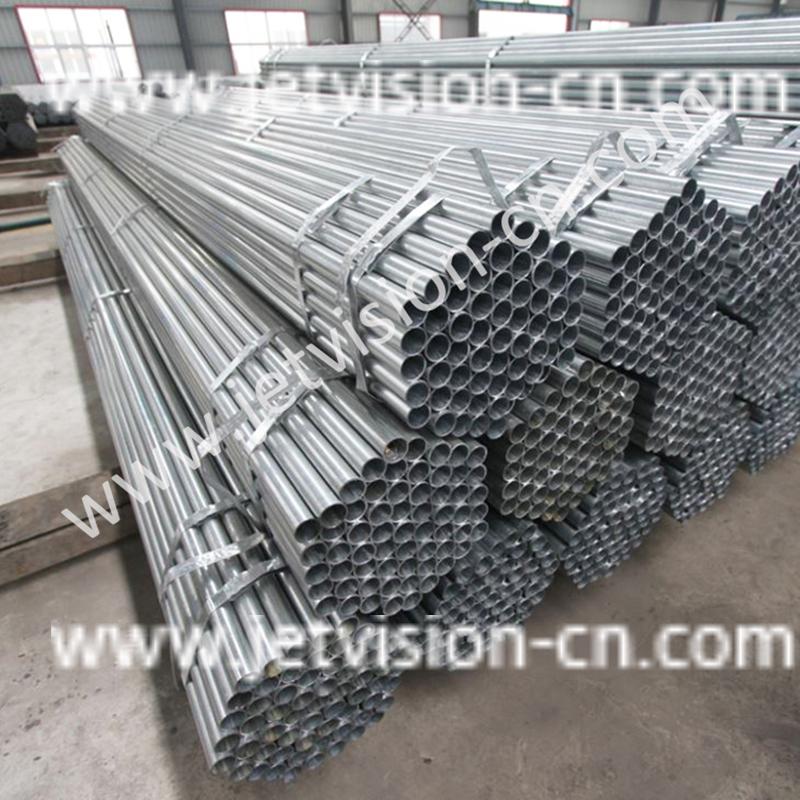

High Quality Hot Dipped Galvanizing Steel Pipe

Galvanized steel pipes are usually coated with zinc on the outside of low carbon steel. The galvanized layer is usually 20 um thick. The melting point of zinc is 419 C and the boiling point is about 908 C. In welding, zinc melts into liquid and floats on the surface of the molten pool or at the root of the weld. Zinc has a high solid solubility in iron. Zinc liquid will etch weld metal along grain boundary. Low melting point zinc will form "liquid metal embrittlement". At the same time, zinc and iron can form intermetallic brittle compounds. These brittle phases reduce the plasticity of weld metal and cause cracks under tensile stress. If fillet welds, especially T-joints, are most prone to penetrating cracks.

|

Product name |

High Quality Hot Dipped Galvanizing Steel Pipe |

|

Technique |

Hot rolled |

|

Standard |

ASME B36.10, JIS3444,GB/T3091,BS 1387,BS1139,DIN2444 |

|

Shape |

Round |

|

Specification |

OD: 21.3mm~660mm WT: 1mm~17.5mm Length:5.8 Mtr/11.8Mtr or Fixed Length |

|

Surface treatment |

Bared,Galvanized,Oiled,Color Paint,3PE;Or other Anti-corrosive treatment |

|

Pipe type |

Welded steel pipe(round/square/rectangular) |

|

item |

Specification |

OD(mm) |

W.T |

Minimum W.T |

6M Fixed length |

||

|

O.D. |

Inch |

Rice weight |

root weight |

||||

|

1 |

DN15 |

1/2 |

21.3 |

2.8 |

2.45 |

1.36 |

8.14 |

|

2 |

DN20 |

3/4 |

26.9 |

2.8 |

2.45 |

1.76 |

10.56 |

|

3 |

DN32 |

1 |

33.7 |

3.2 |

2.8 |

2.554 |

15.32 |

|

4 |

DN40 |

1.25 |

42.4 |

3.5 |

3.06 |

3.56 |

21.36 |

|

5 |

DN50 |

1.5 |

48.3 |

3.5 |

3.06 |

4.1 |

24.6 |

|

6 |

DN65 |

2 |

60.3 |

3.8 |

3.325 |

5.607 |

33.64 |

|

7 |

DN80 |

2.5 |

76.1 |

4 |

3.5 |

7.536 |

45.21 |

|

8 |

DN100 |

3 |

88.9 |

4 |

|

8.88 |

53.28 |

|

9 |

DN125 |

4 |

114.3 |

4 |

|

11.53 |

69.18 |

|

10 |

DN150 |

5 |

140 |

4.5 |

|

15.942 |

98.65 |

|

11 |

DN150 |

6 |

168.3 |

4.5 |

|

19.27 |

115.62 |

|

12 |

DN200 |

8 |

219.1 |

6 |

|

|

|

|

13 |

DN200 |

8 |

219.1 |

6.5 |

|

36.12 |

216.7 |

1.Uncoiling--2 Leveling--3 End cutting--4 End shearing weldling--5 Super coil accumulator --6. Edge cutting--7 Ultrasonic detection--8 Forming--9 Electric induction welding--10.Ultrasonic detection for weld seam--11. Medium frequency heat treatment--12, Air cooling--13. Water cooling --14Sizing--15 Flying cutting--16 Flush-out-- 17. Cropping--18 Flattening,testing--19, Straightening-- 20. End facing and bevelling--21 Hydrodynamic testing--22 Ultrasonic detection for weld seam- 23, Ultrasonic detection for pipe end --24 Visual and dimensions inspection--25.Weighting and measuring

Packaging Details

1.Bundling with steel strip.

2. Galvanized and packing with plastic wrap.

3. In bulk or containers.

4. Packing in wooden case.

5. As customer's requirement.

Payment Terms︰ TT/LC/Paypal/Western/Moneygram